Oops ! Our English website is under development, we expect the development to be over by June , We highly regret the inconvenience caused.

Kindly bear with us and for enquiries please contact mail@kinlong.com .

Oops ! Our English website is under development, we expect the development to be over by June , We highly regret the inconvenience caused.

Kindly bear with us and for enquiries please contact mail@kinlong.com .

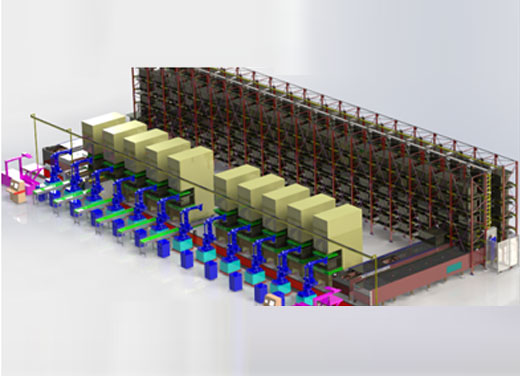

说明:

1.模具库布置在冲床后侧,在冲压生产线两端分别布置上下模输送线,在冲床前

面布置自动换模台车。

2.备模时,堆垛机从模具库将准备换的模具送到上模输送线上。

3.换模时,自动换模台车将输送线上模具送到待换模的冲床上,并将换下的模具

送回到下模输送线上,完成冲床(单机)的换模流程。

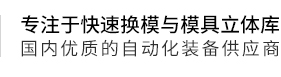

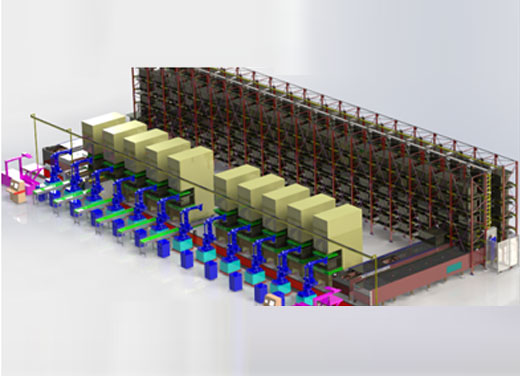

说明:

1.模具库布置在冲床后侧,在冲压生产线两端分别布置上下模输送线,在冲床前面布置自动换模台车。

2.备模时,堆垛机从模具库将准备换的模具送到上模输送线上。

3.换模时,自动换模台车将输送线上模具送到待换模的冲床上,并将换下的模具送回到下模输送线上,完成冲床(单机)的换模流程。

特点:

1.模具从冲床侧向进出,国内首创;

2.多台冲床同时换模,效率高

3.结构紧凑,占地面积小,空间利用率高

4.模具准备不占用生产时间